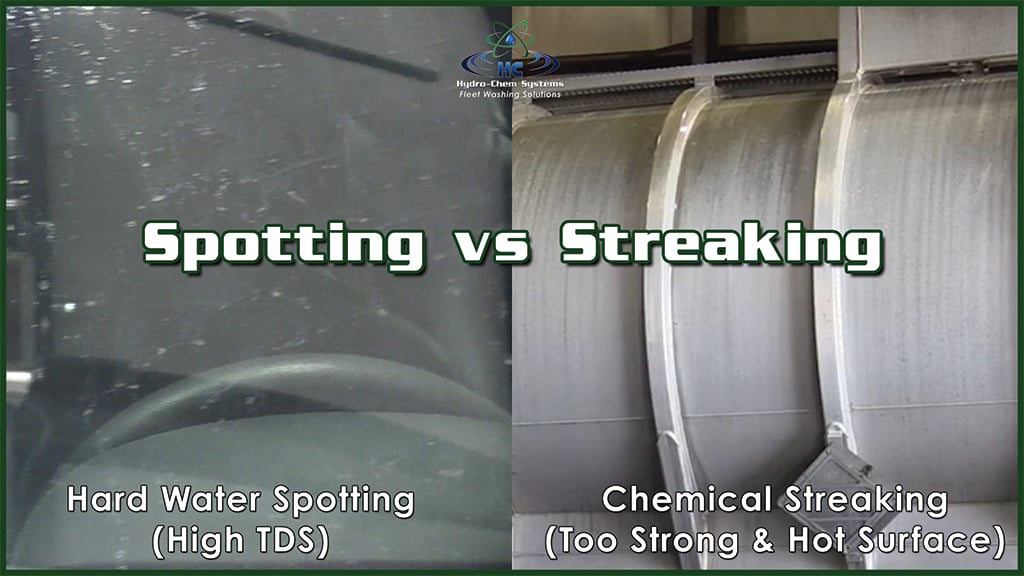

Spotting and Streaking in Truck Washing: Causes and Cures

When it comes to keeping your big trucks and fleets looking their best, dealing with spotting and streaking after a wash can be a real headache. These issues often get mistaken for soap-related problems, but in reality, they might have a different source. To tackle spotting and streaking effectively, let’s dig deeper into what can cause these problems and find the right solutions.

Spotting and Water Quality:

Spotting can occur when you're rinsing off your vehicles with hard water, which might be rich in minerals like calcium and magnesium. As this hard water dries on the truck's surface, it leaves behind those pesky mineral deposits that create those unsightly spots.

What Can Lead to Spotting:

- Mineral-Laden (Hard) Water Sources: If your area's water supply is high in mineral content, you're more likely to experience spotting issues. These minerals in the water mix with soap residue, or hang around in your rinse water, and stubbornly stick to your vehicle as it dries.

- Reclaimed Water: Dirty reclaimed water can contain impurities, soap residue, and even suspended solids from previous washes. If this untreated reclaimed water is used in the rinsing process, it can actually make spotting issues even worse.

- Overspray: Detergent or water residue from washing other sections of the vehicles or others nearby can be blown by the wind or splashed onto a cleaned surface.

Solving the Spotting Mystery:

- Water Softeners: Installing a water softener is an excellent solution against hard water spotting. These systems work their magic by swapping minerals for sodium ions, ensuring a cleaner rinse and improved chemical performance.

- Spot-Free Rinses: The best solution against water spotting is a spot-free rinsing system. These systems use ionization technology to break down mineral ions in the water, preventing them from bonding with your vehicle's surface during drying.

- Maintain Reclaim or Use Fresh Water: Making sure the final step of the wash process has water that is as ‘clean’ as possible - this could mean more investment into your reclaim system, or using fresh water only for the rinse.

- Work with the Wind Direction & Check Cleaned Surfaces for Overspray: If washing outdoors in strong wind conditions, monitor the direction. Begin washing upwind to prevent wash water from spraying onto clean vehicles. When washing multiple vehicles in close proximity, check cleaned surfaces for overspray and rinse when needed. This is especially important when cleaning tankers as wash water is more likely to carry over to the opposite side of the trailer.

Streaking and Too Strong Soap

Unlike spotting, streaking is often linked to the concentration of soap used during the wash, and the level of rinsing. When soap is applied too strongly, it can leave behind streaks and uneven marks on your vehicle's surface. Streaking can also be caused by detergents “weeping” or leaking out from the seams on the vehicle surfaces or lug nut covers on the wheels.

What Can Causes Streaking:

- Overly Concentrated Soap: A main culprit behind streaking is using a soap solution that's too strong. This often happens due to miscalculations in dilution or incorrect settings on your washing equipment.

- Temperature: It’s not uncommon to end up with streaking if you apply a strong soap or acid, especially if there are external factors impacting the temperature. This can include a vehicle coming straight off the road still hot, a warm or sunny day, or even your water temperature!

- Poor Rinsing: If the rinsing process is not done thoroughly, it can leave behind detergent residue on the surface, resulting in streaks after drying.

Solutions for Streaking:

- Talk to Your Equipment and Detergent Provider: To prevent streaking, it's always a good idea to chat with your equipment supplier or the folks you bought your gear from. It may be a change in detergents, concentration of your soap, or adding something like a metering tip to control the level of soap being applied.

- Process Adjustments Based On Temperature: Washing a vehicle in smaller sections when the temperature is particularly warm or hot will help you control the detergent application and prevent it from drying on the surface. You can also try to cool off the vehicle with cool water before washing it, or wash with cold water.

- Rinse Properly: Ensure that the rinsing process is very thorough and covers the entire vehicle surface, pay special attention to tighter areas. Increasing water pressure and/or volume can also help provide a proper rinse. Timing your rinse is important as well – it’s important to not allow the soap to dry on the surface.

- Check for “Weeping Spots”: Detergent residue and rinse water can weep out of seams & lug nut covers. While rinsing, try to avoid direct pressure onto the seams of the chassis body, trailer frame rails, or lug nut covers. Using a sweeping motion with a flood rinse can reduce this from happening, but you should also double-check these areas after washing and re-rinse any weeps.

In the world of big truck and fleet washing, spotting and streaking are two unique challenges that can pop up. Understanding what causes these problems and applying the right fixes is crucial for keeping vehicles looking sharp and ensuring customer satisfaction. By tackling these issues head-on, you can not only protect the fleet's appearance but also enhance your standing in the industry.