Belt Drive Pressure Washers vs Direct Drive: Which is Better?

Is a belt drive pressure washer pump better than a direct drive pump? It’s a question many people have when it comes to choosing the right power washer for cleaning their fleet. We've tried both pressure washer pumps to see which is better.

In this article, we explain how each pump works and look at the pros and cons of each type of pump, so you can make the best decision for your specific needs.

What is a Direct Drive Pressure Washer Pump?

A direct drive pressure washer or direct drive pump gets its name because it is directly connected to the engine. It works by sliding a hollow shaft onto the motor's drive shaft, which allows it to match the engine's RPM (Rotations per Minute).

Advantages of a Direct Drive Pump

-

Its design makes it considerably more compact in size and transportable than a belt drive pump.

-

Direct-driven systems have a much lower upfront cost than belt-driven systems.

-

They typically don’t require as much time spent on general maintenance.

Disadvantages of a Direct Drive Pump

-

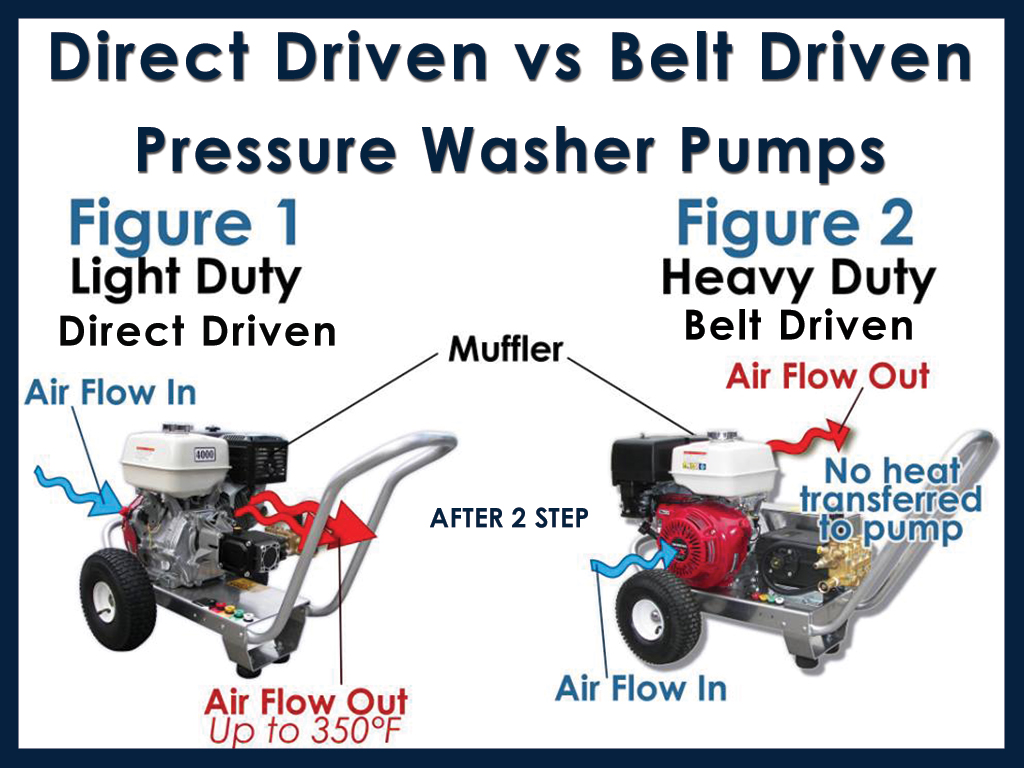

It experiences more wear and tear over time because the pump is mounted directly to the back of an engine running at 250°F to 900°F (Figure 1).

-

It also heats up much more than a belt drive pump because the radiant heat from the muffler is also transferred to the pump assembly and you have metal-to-metal heat transfer since the pump is driven by the crankshaft of the engine.

-

Vibrations from the direct drive pump mounted to the engine also can decrease the pump’s longevity and can often damage the crankshaft of the engine.

- They do not draw water well from a tank and will need to be fed through a pressurized hose.

What is a Belt Drive Pressure Washer Pump?

The engine in a belt drive pressure washer works by using a pulley-and-belt system to drive the pump. Ambient temperature air is drawn in from the front recoil side of the engine, and then passes over the outside cooling fins of the engine.

The pump is also mounted on the far right side of the frame instead of being mounted directly to the engine and has a much lower RPM than a direct drive pump, ranging from about 900-1400 RPM.

Advantages of a Belt Drive Pump

-

Belt-driven pumps rotate up to 1,000,000 times less per day compared to a direct drive pump and last up to 20 times longer.

-

They don’t need to be replaced as often as direct drive pumps.

-

Belt drive pumps have no extreme heat transfer problems, leading to much longer bearing and crankcase life (Figure 2).

-

They can draw water easily from a water tank because it has a slower and longer plunger pull.

-

Experiences fewer vibrations from the engine because it’s not directly attached to it

-

It has a much lower overall cost of ownership

Disadvantages of a Belt Drive Pump

-

They are far more expensive when you first purchase them.

-

They are less efficient because of the constant friction with the belts.

Which Pressure Washer Pump is Better for Your Business?

It depends on what your specific needs are. Direct drive pumps have a use for smaller operations because they are more transportable and less expensive. On the other hand, belt drive pumps don’t need to be pressure-fed water, can be used more often, and last longer over time.

So if you are washing a whole fleet of trucks, especially on a regular basis, then you should probably choose a belt drive pressure pump.

The upfront investment when done alongside regular maintenance will cost less money in the long run.

If you are still having trouble choosing the right power washer, then talk to one of our advisors. With more than 50 years of experience washing vehicles, we’ll help you find the right solution for your needs.